Parallel connect the lead wires for best torque over the widest speed range

NEMA Frame Stepper MotorsIf not enough current is available from the drive, series connect the lead wires for full torque at low speeds

Keep motor case temperature below 100 °C. This can be achieved by lowering the motor current or limiting the duty cycle

Allow sufficient time to accelerate load

Use a microstepping drive for smoothest motor performance over a wide speed range

For open loop operation, size the motor with a 30-50% torque margin at speed. Including an encoder in the system and using a Stall Prevention feature may allow operation all the way down to a 0% torque margin

Do not disassemble motors. A significant reduction in motor performance will result

Do not machine shafts without consulting Electromate® first

Do not disconnect motor from drive while power is applied. Remove power from the drive before disconnecting the motor

Do not use holding torque/detent torque of motor as fail-safe brake

Use an Electromate® recommended stepper drive with your step motor to ensure optimal performance.

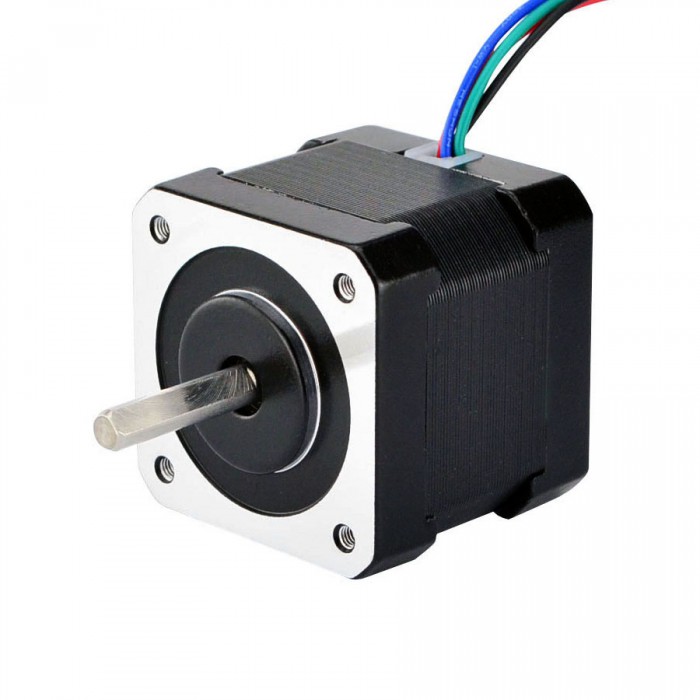

Electromate® sells a family of 2-phase hybrid type step motors with a 1.8° step angle in NEMA frame sizes from NEMA 6, NEMA 8,nema 11 to NEMA 42 motor. Stepper motors from Electromate® are available in 4, 6 or 8 lead configurations for bipolar or unipolar operation. All motors can be wired in series or parallel, depending on the requirement. Motors are available with optional rear shaft extensions, encoders, brakes, cables, gearboxes and IP65 sealing.

https://www.voubs.com/user/betty-alan/167261/fullinfo