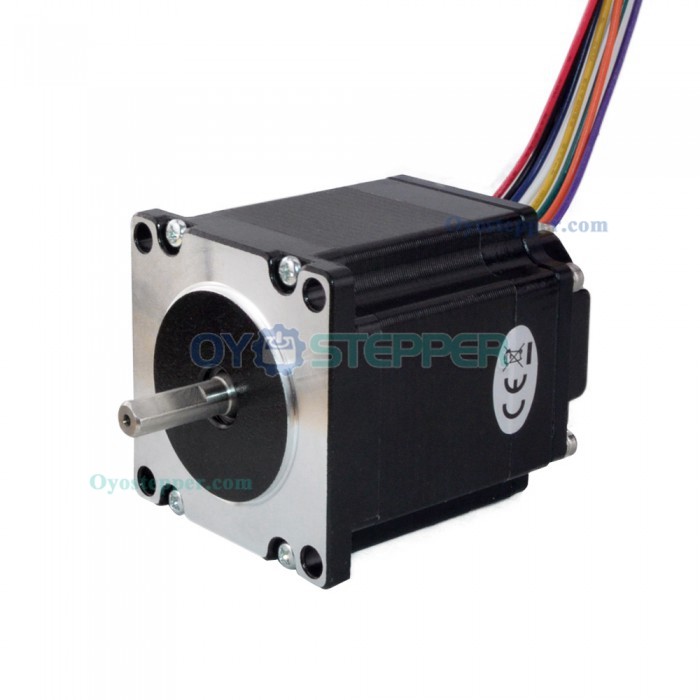

The stepper motor driver and motor can be integrated into one unit, which is an integrated motor. The manufacturer provides various combinations of integrated stepper motor driver combinations, each with its own advantages and disadvantages.

.jpg)

The advantages of integrated stepper motors include easy placement, reduced wiring complexity, faster system setup and construction, and motor driver compatibility. In addition, an integrated unit integrating the control system is also provided.

Easy on-site layout may be the most significant advantage of integrated motors. They do not require wiring between the driver and motor, and can be easily placed in the appropriate location and connected to the controller. This means that settings can be made faster to transition the motion control system from design drawings to production time in a short period of time.

Meanwhile, reducing wiring complexity means that engineers do not have to worry about whether the input and output are correctly connected between the driver and motor. Unipolar or bipolar wiring is no longer an issue. Similarly, interference between cables is reduced, and communication is greatly enhanced.

Integrated motors also mean good compatibility between the motor and driver. It can be used together for they are provided together by the manufacturer. It can reduce the workload during the torque speed curve, as these have already taken into account the drive. For example, there is no need to worry about whether the driver provides the correct type of signal or uses the correct voltage, as all of these have been resolved. If the integrated unit comes with controls, it may be simpler and can handle most control operations. Meanwhile, the merged units can now be connected to other units, which is particularly useful in the Internet of Things.

The main drawback of this setting is the lack of implementation flexibility and potential supplier chain, which leads to troubleshooting issues and equipment maintenance changes. Because the drive motor combination is a unit, it is usually only applicable to certain applications and not to other applications. In addition, if the driver needs to be replaced but the motor is functioning properly, the entire unit can only be replaced.