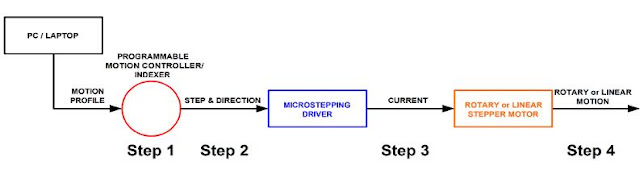

Stepper motor control circuit is a simple and low-cost circuit, mainly used in low power applications. The circuit is shown in figure, which consist 555 timers IC as stable multi-vibrator. The frequency is calculated by using below given relationship:

Frequency = 1/T = 1.45/(RA + 2RB)C Where RA = RB = R2 = R3 = 4.7 kilo-ohm and C = C2 = 100 µF.

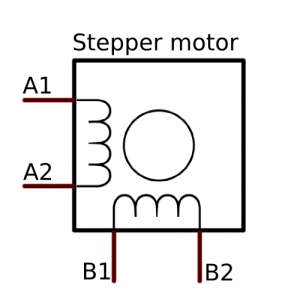

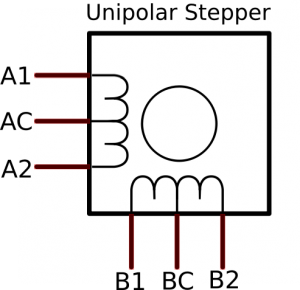

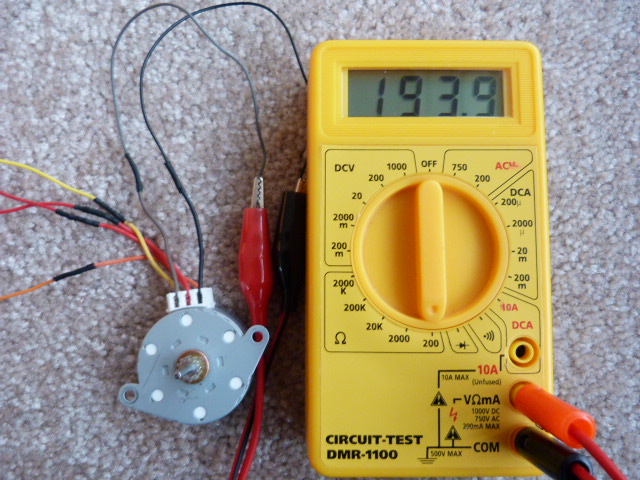

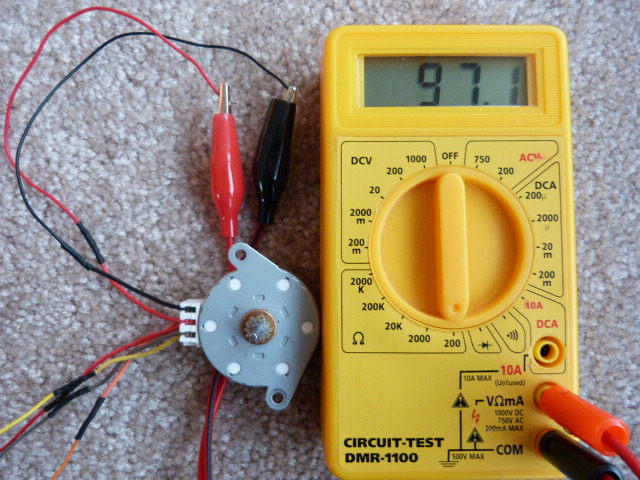

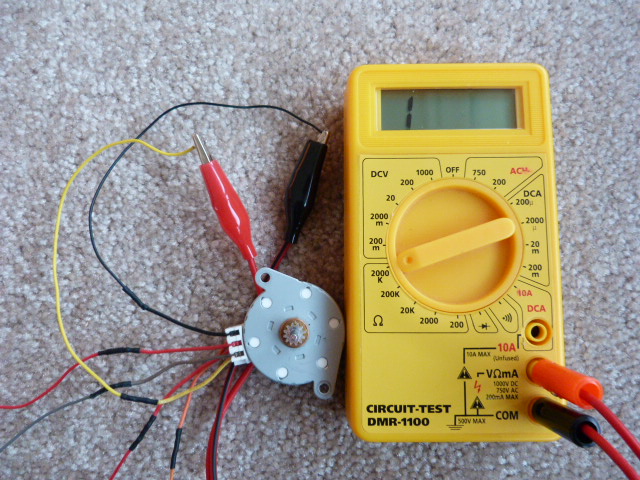

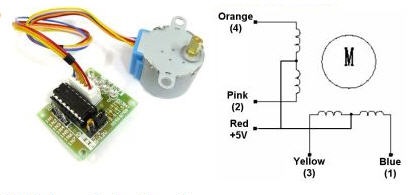

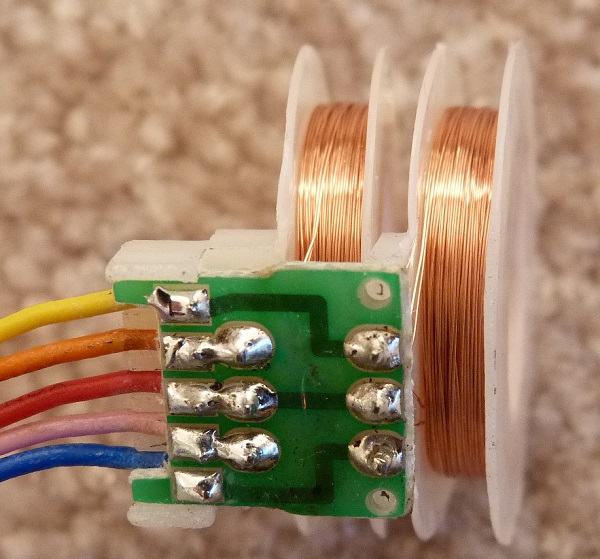

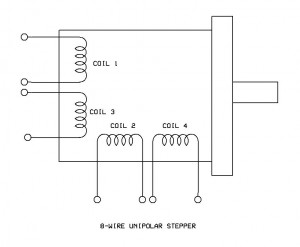

The output of timer is used as clock for two 7474 dual ‘D’ flip-flops (U4 and U3) configured as a ring counter. When power is initially switched on, only the first flip-flop is set (i.e. Q output at pin 5 of U3 will be at logic ‘1’) and the other three flip-flops are reset (i.e. output of Q is at logic 0). On receipt of a clock pulse, the logic ‘1’ output of the first flip-flop gets shifted to the second flip-flop (pin 9 of U3). Thus logic 1 output keeps shifting in a circular manner with every clock pulse. Q outputs of all the four flip-flops are amplified by Darling-ton transistor arrays inside ULN2003 (U2) and connected to the stepper motor windings orange ,brown, yellow, black to 16, 15 ,14, 13 of ULN2003 and the red to +ve supply.

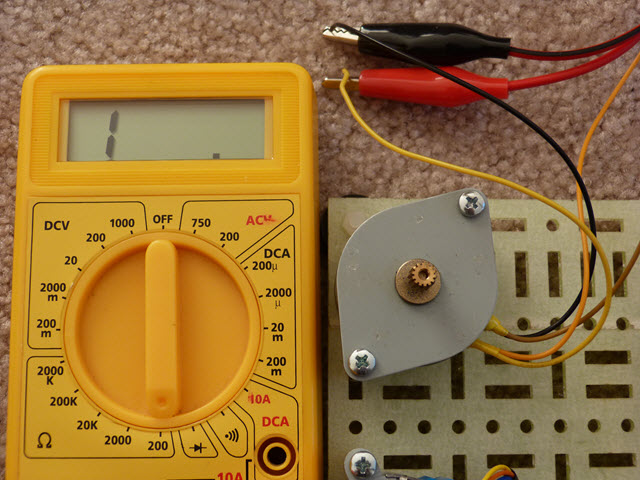

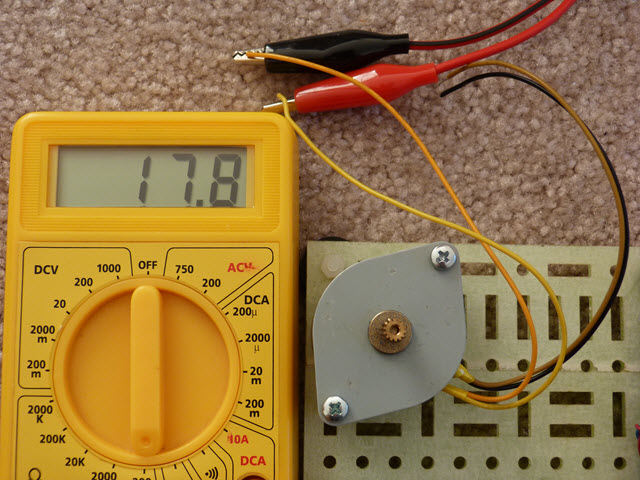

The common point of the winding is connected to +12V DC CNC power supply, which is also connected to pin 9 of ULN2003. The color code used for the windings is may vary form make to make. When the power is switched on, the control signal connected to SET pin of the first flip-flop and CLR pins of the other three flip-flops goes active ‘low’ (because of the power-on-reset circuit formed by R1-C1 combination) to set the first flip-flop and reset the remaining three flip-flops. On reset, Q1 of IC3 goes ‘high’ while all other Q outputs go ‘low’. External reset can be activated by pressing the reset switch. By pressing the reset switch, you can stop the stepper motor. The motor again starts rotating in the same direction by releasing the reset switch.

Now you have got an idea about the types of super motors and its applications if you have any queries on this topic or on the electrical and electronic projects leave the comments below.

Frequency = 1/T = 1.45/(RA + 2RB)C Where RA = RB = R2 = R3 = 4.7 kilo-ohm and C = C2 = 100 µF.

The output of timer is used as clock for two 7474 dual ‘D’ flip-flops (U4 and U3) configured as a ring counter. When power is initially switched on, only the first flip-flop is set (i.e. Q output at pin 5 of U3 will be at logic ‘1’) and the other three flip-flops are reset (i.e. output of Q is at logic 0). On receipt of a clock pulse, the logic ‘1’ output of the first flip-flop gets shifted to the second flip-flop (pin 9 of U3). Thus logic 1 output keeps shifting in a circular manner with every clock pulse. Q outputs of all the four flip-flops are amplified by Darling-ton transistor arrays inside ULN2003 (U2) and connected to the stepper motor windings orange ,brown, yellow, black to 16, 15 ,14, 13 of ULN2003 and the red to +ve supply.

The common point of the winding is connected to +12V DC CNC power supply, which is also connected to pin 9 of ULN2003. The color code used for the windings is may vary form make to make. When the power is switched on, the control signal connected to SET pin of the first flip-flop and CLR pins of the other three flip-flops goes active ‘low’ (because of the power-on-reset circuit formed by R1-C1 combination) to set the first flip-flop and reset the remaining three flip-flops. On reset, Q1 of IC3 goes ‘high’ while all other Q outputs go ‘low’. External reset can be activated by pressing the reset switch. By pressing the reset switch, you can stop the stepper motor. The motor again starts rotating in the same direction by releasing the reset switch.

Now you have got an idea about the types of super motors and its applications if you have any queries on this topic or on the electrical and electronic projects leave the comments below.