NEMA 34 is a high torque hybrid bipolar stepping motor

with a 3.4×3.4 inch faceplate. Hybrid stepper has the combination of

the features of the Variable Reluctance Stepper Motor and Permanent

Magnet Stepper Motor. This motor has a step angle of 1.8 deg., this

means that it has 200 steps per revolution and for every step it will

cover 1.8°. This NEMA 34 is a 2-Phase motor with 4 wires. Compatible

controllers for this motor are CW230, CW250 and CW860.

How to use NEMA 34 Stepper Motor

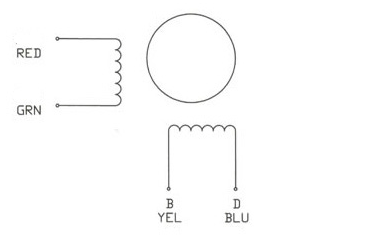

As mentioned above this stepper motor draws high current so instead of controlling it directly, use an appropriately powerful stepper motor drivers like cw230. Wiring diagram for NEMA 34 Stepper motor is given below:

As shown in wiring diagram there are four wires of different colours i.e. Red, Green, Yellow and Blue. These wires are connected to two different coils. Red and Green connected to one coil while Yellow and Blue are connected to other.

To rotate the motor coils are energized in a logical sequence. To rotate the motor in anticlockwise motion of the rotor the phases are energized in the following sequence +A, +B, -A, -B, +B, +A and for the clockwise rotation, the sequence is +A, -B, +B, +A……..

Stepper Motor Applications

CNC machines

Precise control machines

3D printer/prototyping machines (e.g. RepRap)

Laser cutters

Pick and place machines

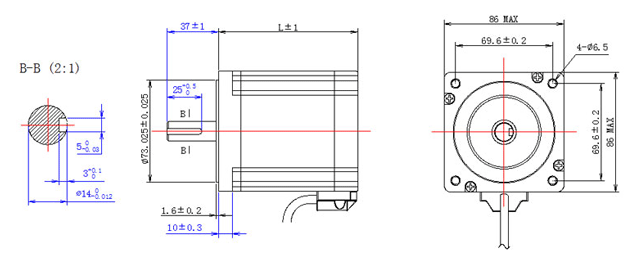

NEMA 34 Stepper Motor Dimensions

See more:

https://www.oyostepper.com/article-1091--NEMA-34-Stepper-Motor-Applications-and-Dimensions.html

How to use NEMA 34 Stepper Motor

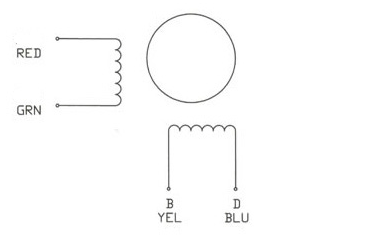

As mentioned above this stepper motor draws high current so instead of controlling it directly, use an appropriately powerful stepper motor drivers like cw230. Wiring diagram for NEMA 34 Stepper motor is given below:

As shown in wiring diagram there are four wires of different colours i.e. Red, Green, Yellow and Blue. These wires are connected to two different coils. Red and Green connected to one coil while Yellow and Blue are connected to other.

To rotate the motor coils are energized in a logical sequence. To rotate the motor in anticlockwise motion of the rotor the phases are energized in the following sequence +A, +B, -A, -B, +B, +A and for the clockwise rotation, the sequence is +A, -B, +B, +A……..

Stepper Motor Applications

CNC machines

Precise control machines

3D printer/prototyping machines (e.g. RepRap)

Laser cutters

Pick and place machines

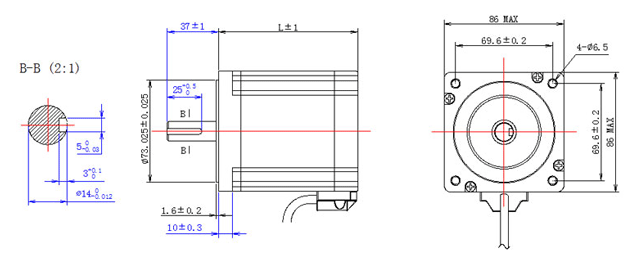

NEMA 34 Stepper Motor Dimensions

See more:

https://www.oyostepper.com/article-1091--NEMA-34-Stepper-Motor-Applications-and-Dimensions.html