Conventional

stepper motors cannot accommodate large diameter hollow shafts without

sacrificing torque and performance. Torque is dependent on the size of the

magnet placed in the rotor. A large diameter shaft reduces space available for

the magnet, thus sacrificing torque. Since we’ve moved the magnet from the

rotor into the stator stack, we can accommodate a large shaft without

sacrificing torque or performance. Oyostepper, the motion component and systems

specialist, further expands its range of stepper motors with the new

competitively priced HH series hollow shaft motors from its USA distribution

partner Applied Motion Products Inc. (AMP).

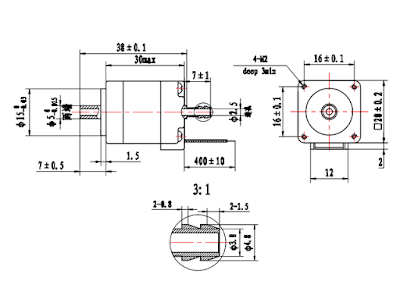

With high-torque NEMA 17 and 23 motor frame options in a choice of stack lengths, the hollow shaft facilitates direct assembly of a lead screw without the need for a coupling - keeping hardware to a minimum and simplifying design for machine builders. The hollow shaft stepper motor also allows customised shafts or other power transmission components to be quickly added to the motor without the often-long lead times that specials may take and also enables small quantities of specials to be produced at reasonable cost. The internal shaft diameter for the 17 and 23 frame motors is 5 mm and 8 mm respectively. The holding torque across the 2-phase HH series ranges from 0.45 to 2.3 Nm with current ratings from 2 to 3 A per phase (series).

Large

Holow Shaft Up to 11 mm in Diameter

The

motors are supplied with a detachable lead/connector pigtail for

straightforward installation in the customer’s application. The 200/step/rev

motors can be used with stepper drives across the AMP range, including the micro

stepper motor for sale ST5 which offers sophisticated current control and

multiple motion control options from simple streaming commands to communication.

And it works closely with a small number of global motion control manufacturers

and with its own in-house design and manufacturing capability the Hampshire

based motion specialist offers complete integrated mechatronics assemblies with

customised mechanics, gearheads and other power train components.

No comments:

Post a Comment