The closed-loop method is also referred to as a sinusoidal commutation via an encoder with a field-oriented control. The heart of closed-loop technology is power-adjusted current control and feedback of control signals. Through the encoder, the rotor position is recorded and sinusoidal phase currents are generated in the motor coils. Vector control of the magnetic field ensures that the magnetic field of the stator is always perpendicular to that of the rotor and that the field strength corresponds precisely to the required torque. The current level thus controlled in the windings provides a uniform motor force and results in an especially smooth-running hybrid step motor that can be precisely regulated.

Closed loop stepper motors are an alternative when the application requires:

High torque at speeds up to 500rpm and a compact, economical solution without a gearbox,

Rapid commissioning without expensive tuning,

A load to be held in position while at a standstill,

Avoidance of transient and free oscillation behavior (hunting), which is typical of servo motors and occurs especially on variable loads and pulsation, leading to intolerable step errors. On sudden load changes, servo motors miss their positions and must be corrected.

Ideal application areas for best closed loop stepper motors:

Multiple axis applications (serial, Ethernet, EtherCAT, CANopen)

Positioning tasks with load changes

Winding applications

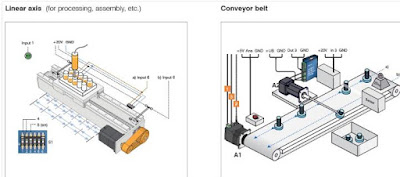

Belt drives (start/stop, positioning)

Dosing pumps, filler systems

Semi-conductor mounting

Wafer production

Textile machines/industrial sewing machines

Robotics

Testing and inspection systems

Applications that require quiet operation, short settling times and precision positioning.

WHAT ARE LINEAR STEPPER MOTORS?

Closed loop stepper motors are an alternative when the application requires:

High torque at speeds up to 500rpm and a compact, economical solution without a gearbox,

Rapid commissioning without expensive tuning,

A load to be held in position while at a standstill,

Avoidance of transient and free oscillation behavior (hunting), which is typical of servo motors and occurs especially on variable loads and pulsation, leading to intolerable step errors. On sudden load changes, servo motors miss their positions and must be corrected.

Ideal application areas for best closed loop stepper motors:

Multiple axis applications (serial, Ethernet, EtherCAT, CANopen)

Positioning tasks with load changes

Winding applications

Belt drives (start/stop, positioning)

Dosing pumps, filler systems

Semi-conductor mounting

Wafer production

Textile machines/industrial sewing machines

Robotics

Testing and inspection systems

Applications that require quiet operation, short settling times and precision positioning.

WHAT ARE LINEAR STEPPER MOTORS?

No comments:

Post a Comment